PRODUCT

PRODUCT MEASUREMENT & PROCESS CONTROL

Instrumentation and control equipment from leading manufacturer for use

in an industrial production such as Wire & Cable, Steel & Metals, Pipe & Tube, Converting and etc…

READ CLOSE

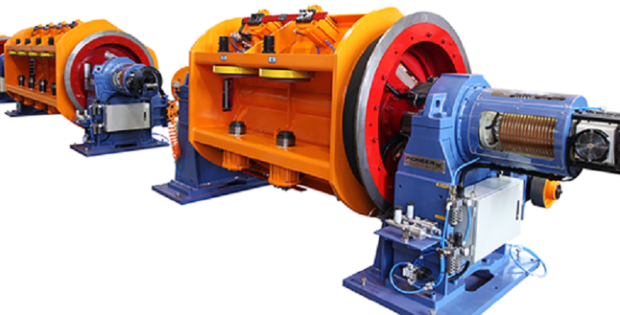

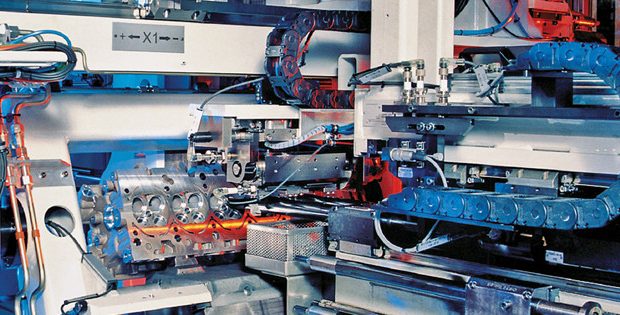

Production Machinery

While providing instrumentation and control equipment are a given, we also

provide our customers the best design, technology, machinery in manufacturing processes electric wire and cable, which high quality at a very competitive price to fit their needs and suitable for businesses.

READ CLOSE

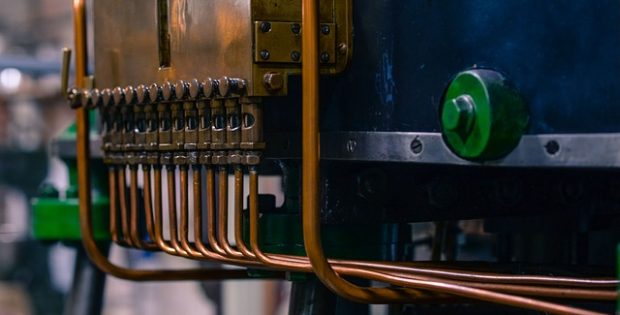

Industry 4.0

We have the professional manufacturer “Pioneer” who is the largest wire and

cable machinery manufacturer in Taiwan. We are our greatest honor to

introduce to you for their newest development, SmartFA-S7, an IoT based factory integration system to help wire & cable factory to migrate a smart factory.

READ It has been more than 3 years since they started to develop this system. After the first prototype we build 2 years ago, more than 10 engineers of master and doctor degree spent thousands hours working days and nights to complete and polish every single function blocks in this system. Now, it’s time to show their revolutionary product to all our customers. It’s not only about to change the way cable factories are operated and managed, The implementation of the Smart Factory significantly upgrades the productivity, cost management, quality control and overall efficiency and flexibility of the production process. Their system is based around This application provides real – time information flowing in from all the production lines, and every necessary elements to improve your business significantly in following aspects: To help customers implement SmartFA in their existing factories fast and smoothly, they have developed several techniques: Production Line Integration Digital Core Designed for Wire&Cable Modularized Components and Pipeline Implementation CLOSE

but it is also a milestone for them at Pioneer, as we transform ourselves from machine makers to solution providers.

establishing a network between the production lines and a fully customizable, access controlled, visually oriented application that can be accessed from

any fixed and portable devices.

To minimize the overhead cost in process and during process change.

To produce more products with less man power.

To dig and backtrace from Big data then locate and fix the root of problem on the fly

A highly customized statistical analysis of the mega data, offering real -time report for decision making.

Regardless if they are dealing with brand new lines, existed lines, or very old grandpa lines, they can help you to adapt, interface, upgrade or rebuild all

your production lines to to be compatible with the SmartFA system.

Their system isn’t just collecting data. They have migrated a reputed digital workflow system and included it as a brain of their SmartFA system. With this kernel, it becomes possible and natural to cooperate with high level system such as ERP, MES, ASP, PLM from SAP or Oracle.

Just like a LEGO game, the whole implementation is separated into different layers formed by modularized components which is highly flexible to connect with each other. With this design they can perform multiple implementation

in parallel which greatly shortens overall time to transform the whole factory into a smart factory.